InfraTec, exhibitors at SENSOR + TEST 2022 in Nuremberg, has been developing and manufacturing cutting-edge pyroelectric detectors for over 30 years, and their technology is ubiquitous to some of the world’s most demanding of industrial settings. Recently they launched a digital pyroelectric detector so customers can easily integrate their gas detection equipment into their system and cut costs.

Digital pyroelectric gas detector overview

InfraTec’s digital detector is built around lithium tantalate (LiTaO3)’s optical piezoelectric properties and used for gas analysis and flame detection. These versatile and flexible instruments’ parameters are easily configured with their variable signal processing capabilities. They also provide enhanced electromagnetic compatibility (EMC), as the detector’s signal conversion is spatially concentrated and shielded.

The digital detector features a clock input (pin) to synchronise the radiator and detector clock so that a time signal with a precise sampling rate can be generated. Another innovation is the “fast recovery after saturation“ which detects the override caused by a defective operating status and automatically resets the device to the analogue input stage.

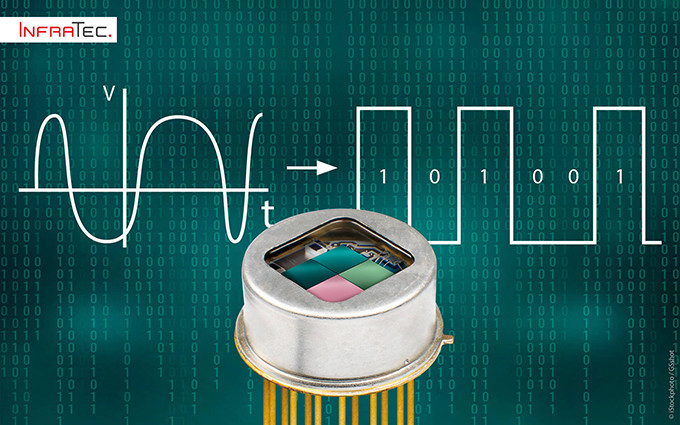

Infratec’s new digital detector will convert an analogue signal, with a 16Bit resolution, directly into a digital signal. The analogue signals can be multiâ€Âstage, adjustably filtered and strengthened. Signal processing is via an ASIC (application-specific integrated circuit) with an integrated A converter, while the analogue input stage acts as a trans-impedance amplifier. Operators obtain a digital measurement signal, which can be read through a standard communication interface and processed immediately.